Holtop Cross-flow Plate Fin Total Heat Exchangers ( Enthalpy Recovery core for energy recovery ventilator)

Product Description:

Working principle The flat plates and the corrugated plates form channels for fresh or exhaust air stream. When the two air steams passing through the exchanger crossly with temperature difference, the energy is recovered.

Working principle The flat plates and the corrugated plates form channels for fresh or exhaust air stream. When the two air steams passing through the exchanger crossly with temperature difference, the energy is recovered.  Performance index

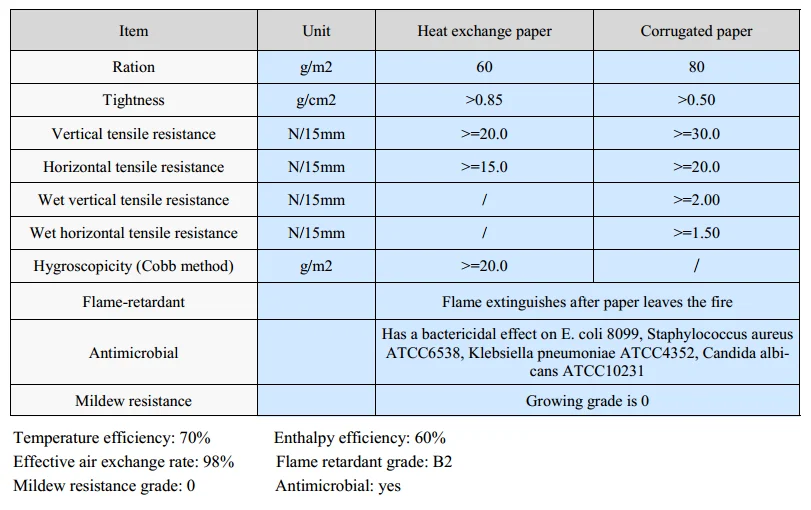

Performance index  E.R. paper performance introduction Heat exchange paper: for heat and moisture exchange, the main performance standards are diathermancy, moisturepenetrability and air permeability. Corrugated paper: to construct the frame for the heat exchanger, flowing passages of the air stream. Anti-bacteria and mold prevent performance The bacteria exists in the damp air, when air goes through the heat exchanger, bacteria may stick on the walls of the exchanger. If the heat exchanger doesn’t have the anti-bacteria ability, it will grow on the inside wall, and then blown into indoor, which will cause indoor air pollution. That is why the anti-bacteria performance is required. The ability of bacterial growth inhibition and killing bacteria, to prevent the production of mold, is an important factor of heat exchanger paper. By adding the bactericides to the surface of paper and the anti-bacteria agents to the slurry, the heat exchanger has abilities to kill bacteria (such as Escherichia coli and staphylococcus) and inhibit fungal (such as Candida albicans) and prevent the bacteria and germ spreading in the air. Holtop heat exchanger paper was tested by Guangzhou Industry Microbe Test Center, and shown the antibacterial effect, and its mildew grade is 0.

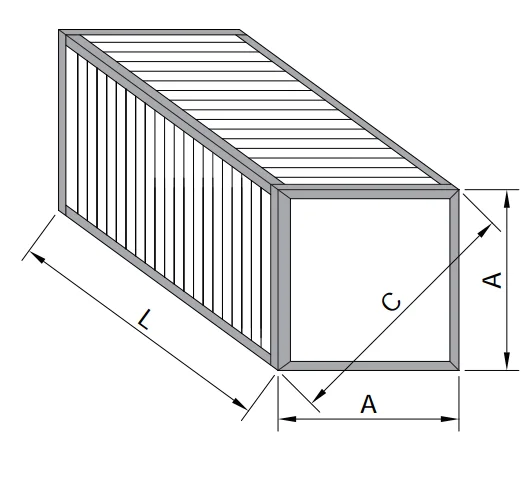

E.R. paper performance introduction Heat exchange paper: for heat and moisture exchange, the main performance standards are diathermancy, moisturepenetrability and air permeability. Corrugated paper: to construct the frame for the heat exchanger, flowing passages of the air stream. Anti-bacteria and mold prevent performance The bacteria exists in the damp air, when air goes through the heat exchanger, bacteria may stick on the walls of the exchanger. If the heat exchanger doesn’t have the anti-bacteria ability, it will grow on the inside wall, and then blown into indoor, which will cause indoor air pollution. That is why the anti-bacteria performance is required. The ability of bacterial growth inhibition and killing bacteria, to prevent the production of mold, is an important factor of heat exchanger paper. By adding the bactericides to the surface of paper and the anti-bacteria agents to the slurry, the heat exchanger has abilities to kill bacteria (such as Escherichia coli and staphylococcus) and inhibit fungal (such as Candida albicans) and prevent the bacteria and germ spreading in the air. Holtop heat exchanger paper was tested by Guangzhou Industry Microbe Test Center, and shown the antibacterial effect, and its mildew grade is 0.  Product Specification The heat exchange paper and corrugated paper are adhesived with waterborne binder, the core and cover are sealed with special sealant to total separate the supply air and exhaust air, in order to keep the structure strength and air tightness and prevent the cross contamination. It is widely applied and the maximum temperature should not exceed 100 C. For size A within 500mm and the size L within 600mm, the heat exchanger is built in one module. For size A bigger than 500mm and size L bigger than 600mm, the heat exchanger is built in multi-modules.

Product Specification The heat exchange paper and corrugated paper are adhesived with waterborne binder, the core and cover are sealed with special sealant to total separate the supply air and exhaust air, in order to keep the structure strength and air tightness and prevent the cross contamination. It is widely applied and the maximum temperature should not exceed 100 C. For size A within 500mm and the size L within 600mm, the heat exchanger is built in one module. For size A bigger than 500mm and size L bigger than 600mm, the heat exchanger is built in multi-modules. | Model | A (mm) | B (mm) | C (mm) | Optional corrugation height (mm) | Remarks |

| HBT-W168/168 | 168 | ≤500 | 240 | 2.0, 2.5 | One module |

| HBT -W202/202 | 202 | ≤500 | 288 | 2.0, 2.5 | |

| HBT -W222/222 | 222 | ≤500 | 317 | 2.0, 2.5 | |

| HBT-W250/250 | 250 | ≤700 | 356 | 2.0, 2.5, 3.5 | |

| HBT-W300/300 | 300 | ≤700 | 427 | 2.0, 2.5, 3.5 | |

| HBT -W350/350 | 350 | ≤700 | 498 | 2.5, 3.5 | |

| HBT -W372/372 | 372 | ≤700 | 529 | 2.5, 3.5 | |

| HBT -W400/400 | 400 | ≤700 | 568 | 2.5, 3.5 | |

| HBT -W472/472 | 472 | ≤550 | 670 | 3.5 | |

| HBT -W500/500 | 500 | ≤550 | 710 | 3.5 | |

| HBT -W552/552 | 552 | ≤550 | 783 | 3.5 | |

| HBT -W600/600 | 600 | ≤550 | 851 | 3.5 | |

| HBT -W652/652 | 652 | ≤550 | 925 | 3.5 | |

| HBT -W700/700 | 700 | ≤550 | 993 | 3.5 | Multi-module combined |

| HBT -W800/800 | 800 | ≤550 | 1134 | 3.5 | |

| HBT-W1000/1000 | 1000 | ≤450 | 1417 | 3.5 | |

| HBT-W1200/1200 | 1200 | ≤450 | 1702 | 3.5 | |

| HBT -W1400/1400 | 1400 | ≤450 | 1985 | 3.5 | |

| HBT -W1600/1600 | 1600 | ≤450 | 2265 | 3.5 |

Applications Used in comfortable air conditioning ventilation system and technical air conditioning ventilation system. Supply air and exhaust air totally separated, heat recovery in winter and cold recovery in Summer -Direct air to air energy exchange -Ideal for both residential and commercial application

Applications Used in comfortable air conditioning ventilation system and technical air conditioning ventilation system. Supply air and exhaust air totally separated, heat recovery in winter and cold recovery in Summer -Direct air to air energy exchange -Ideal for both residential and commercial application - Suitable for airflow 300-60000 m3/h.

- Previous: Cross Counterflow Heat Exchangers

- Next: Sensible Plate Heat Exchanger